Standby power system at Tampa’s Haley VA hospital covers all electrical loads for 120 hours for a 25-structure campus

James A. Haley Veterans’ Hospital in Tampa, Florida, boasts one of the most advanced emergency backup power control systems of any hospital in the United States.

James A. Haley Veterans’ Hospital in Tampa, Florida, boasts one of the most advanced emergency backup power control systems of any hospital in the United States.

Thanks to its recently renovated power plant, few, if any, hospitals have a better power system than the James A. Haley Veterans’ Hospital in Tampa, Florida. At a cost of $47 million, it includes an emergency generator system capable of covering all electrical loads for 120 hours (without refueling).

A teaching hospital affiliated with the University of South Florida College of Medicine, Haley Hospital provides a full range of patient services with state-of-the-art technology and research.

After Hurricane Katrina, the U.S. Department of Veterans Affairs began upgrading emergency power systems at VA hospitals in hurricane zones — upgrades that ensure continuous air conditioning, not just the operation of life-safety and other critical equipment.

The winning bid for Haley Hospital’s power control system and SCADA came from Russelectric, of Hingham, Massachusetts. Russelectric designs, builds, commissions, and services on-site power control systems for mission-critical facilities.

Extra layer of confidence

Byron Taylor, Haley’s Lead Power Plant Operator, says the new system, which provides many new capabilities and allows for future modifications, gives him extra confidence.

“When storms come through, we do not have to worry,” says Taylor. “Once, we saw storms coming and TECO [Tampa Electric Company] asked us to drop off the grid. We fired up our generators and operated on our own power for 17 hours, while TECO concentrated on restoring power to its residential customers. This has happened several other times and we’ve never had a problem.”

Electrical Shop Supervisor Bill Hagen appreciates the quality of the power from the emergency system.

“We get more blips from TECO than we do from our system,” he quips. “It is exceptionally smooth.”

Hagen has no fond memories of the old system, calling it “a major headache.” That system’s nine on-site generators could only cover life-safety loads — 45% of the hospital’s total load — during a utility outage. “We had nothing but problems with it,” Hagen recalls. “We never got it to work in parallel. It couldn’t even generate a monthly testing report.”

In contrast, the new emergency system covers every load for nine buildings, a 15-trailer clinic, and a parking garage — with just seven new 13,200-VAC Caterpillar diesel generators. Supplied by Ring Power, the generators produce 2,200 kW each.

The power of information

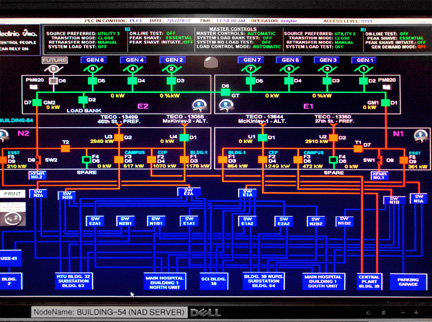

The power control system upgrade also includes a new Russelectric SCADA system, with software and screen displays customized for the hospital’s needs. It provides interactive monitoring, real-time and historical trending, distributed networking, alarm management, and comprehensive reports for the entire power system, not just for the emergency system.

SCADA screen displaying a one-line diagram of the state-of-the-art power system at James A. Haley Veterans’ Hospital, Tampa, Florida.

“The SCADA is so sensitive that it detects and explains even the slightest anomaly, including those in the utility feed,” says Taylor. “Several times we’ve called TECO because we saw something, before they even knew they had a problem! The system capabilities are phenomenal.”

Freedom to test the system

The emergency generators are tested every month in accordance with state and federal regulations. Thanks to the new system’s closed-transition transfer capability, there is no interference with hospital loads. And with no “blip” (power interruption), these tests inconvenience no one.

The system gives Taylor and Hagen the luxury of carrying out tests in two ways. They can parallel the output of all seven generators to the utility feed, or they can test one generator at a time, up to its full output, using a special 2-MW load bank with an independent control panel. Testing can be initiated manually or through SCADA.

“We’ll never again have to pay a testing firm to test an engine to make sure it meets all the requirements,” says Hagen.

Unlike most hospitals, Haley has the luxury of four utility feeds. Normally, it draws from two of these feeds. This means that, except for testing, Haley does not have to start its generators until it loses three or more utility feeds.

With notice from the utility that an outage is likely, Haley personnel can now parallel the utility feeds with their own generators, then switch to on-site power seamlessly (closed-transition transfer). But if there is an unexpected outage (while the automatic transfer switches are being tested), there will be a “blip” of 1 to 10 seconds. For life-safety and other critical loads, the “blip” is only 1 to 3 seconds. “Blips” for other loads are adjustable; most are set for 8-10 seconds.

Technical support always on-call

One of two Russelectric panel boards in Haley Hospital’s power plant control room. The boards include a custom Russelectric SCADA system that allows remote monitoring and control of the hospital’s power.

Taylor and Hagen have high praise for Russelectric’s 24-hour support services. They recall working hand-in-hand with Jim Bourgoin, Russelectric’s local Field Service Engineer, for seven months.

“During installation, Jim helped the contractors interpret the design,” Hagen says. “Afterwards, he stuck around to help us. I already had a background in this, but it took quite a bit of training to really get up to speed.”

Taylor recalls, “There has not been one time when I called Jim — whether at midnight or later — that he hasn’t answered the phone and helped me. And on two occasions, he drove here at 3 or 4 in the morning to correct something that had gone wrong. But it’s not just his responsiveness that’s impressed us. He provides exceptional service, and it’s been that way since day one. To me, that’s worth as much as the system itself.”

For more information, contact: Russelectric, 800-225-5250 or (781) 749-6000, and email: info@russelectric.com.